It was a world’s first and just last month the team from Holland that were responsible for putting it all together, Xilloc, posted a video online to show the world how good the guitar sounds.

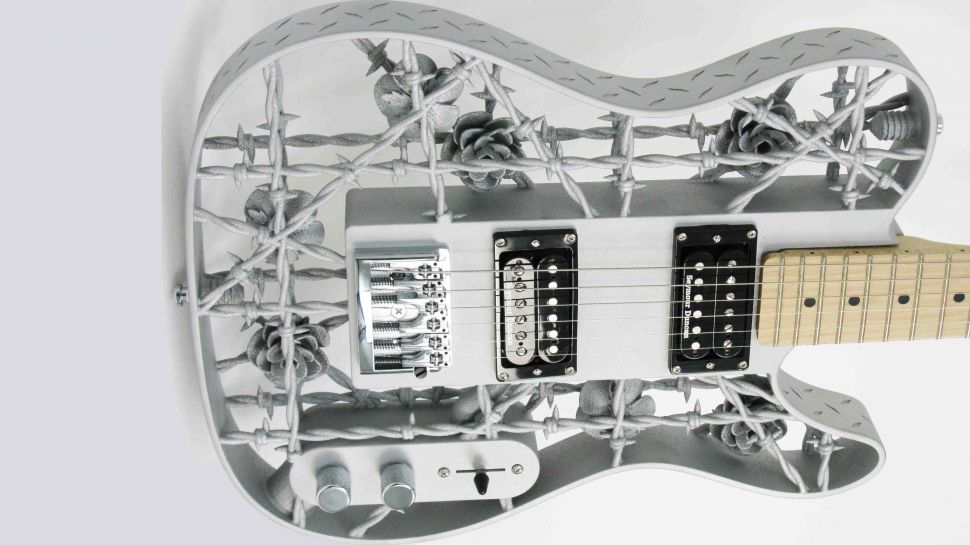

Affectionately known as the Heavy Metal, the guitar is a testament to Diegal’s desire to push the limits of metal 3D printing; “[I also wanted] to better understand the intricacies of the whole process, from ‘design for additive manufacturing’, to the actual 3D printing of the guitar, to the post-processing that is required to go from a 3D-printed metal part straight of the machine to a usable masterpiece,” Diegel said.

In order for the guitar to be printed, Diegel sought out Xilloc. The company is at the forefront of 3D-printing development and the specialise in ceramics, carbon fiber and metals. They used an EOS M400 printer to make Heavy Metal in a single piece using aluminium power at 0.1 mm thick layers. It took a few more days to file, sand and polish the guitar and after strapping on a pair of Seymour Duncan humbuckers, Diegel’s new axe was complete.